Plastic moulding is an essential process in the manufacturing industry. But do you know how it works and what different type of plastic moulding methods are available? In this blog post, we will take a deep dive into the world of plastic moulding and explore everything you need to know about this critical manufacturing process .

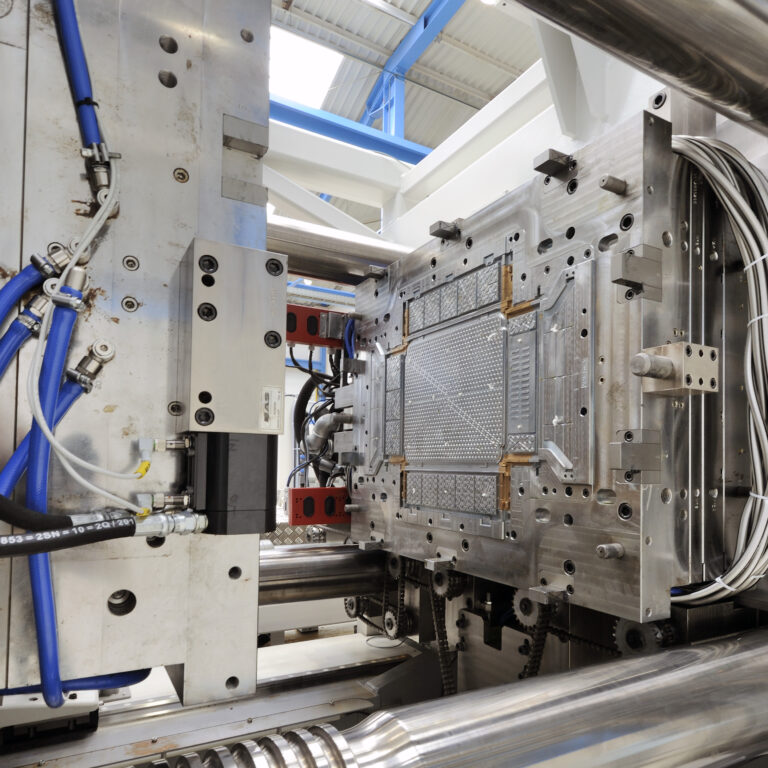

Plastic moulding is the process of creating plastic parts by injecting molten plastic into a mould. The molten plastic then cools and hardens to form the desired shape. There are several types of plastic moulding methods available, including injection moulding, compression moulding, blow moulding, and rotational moulding. Each technique has its own advantages and limitations, and the different moulding processes may or may not be suitable for moulding a particular project depending on several factors, such as the complexity of the part, the material used, and the production volume required.